The Craftsman LT2000 Drive Belt Diagram (Explained How It Works!)

The craftsman lt2000 is a popular riding lawn mower designed for homeowners to easily manage their lawns. One of the most important component is drive belt, responsible for delivering power from the engine to the gearbox and permitting the engagement of the mower deck.

In this article, we will give a detailed explanation to the craftsman lt2000 drive belt diagram, detailing its components, routing, tensioner mechanism, maintenance tips and how it operates.

Additionally, we’ll discuss maintenance advice, resolving common faults, and commonly asked questions pertaining to the drive belt.

The Craftsman Lt2000 Drive Belt Overview

The craftsman lt2000 drive belt is a crucial component in the mower’s power transfer and grass cutting. Made of high-grade rubber, it resists constant strain and tension. To maintain the mower’s performance and lawn, it’s essential to understand its diagram and components.

Regular inspections for wear and damage are crucial to prevent loss of power transfer or belt failure. Replacing the drive belt is essential, and if unsure, consult the mower’s manual or seek professional assistance.

Proper tension adjustment and regular cleaning and lubrication prolong the drive belt’s lifespan and preserve its functionality.

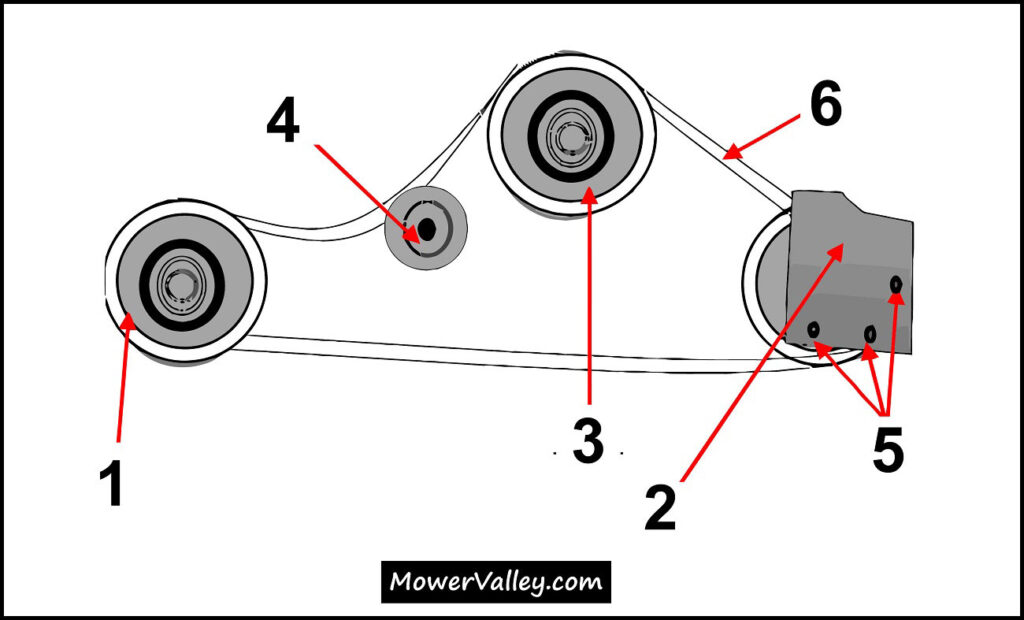

The Craftsman LT2000 Drive Belt Diagram

It is crucial to refer to the exact diagram associated with the craftsman lt2000 mower being worked on due to the many models and years of the mower. This level of care ensures that the drive belt is routed precisely, reducing the possibility of damage to other parts and enhancing the mower’s overall efficiency.

With the help of this diagram, users may navigate the complex system of pulleys, idlers, and tensioners that makes up the drive belt system.

1. Left Hand Double Pulley

2. Right Hand Double Pulley

3. Center Pulley

4. Deck Idler Pulley

5. Self-Tapping Screw Assembly

6. Deck Belt

Craftsman LT2000 Drive Belt Components

There are two main parts to the craftsman lt2000 drive belt system. Let’s know them in a nutshell.

1. Left Hand Double Pulley

The left-hand double pulley offers a convenient solution for moving heavy loads with minimal effort. By employing the double pulley mechanism, the required exertion to move the load is significantly reduced.

This increased mechanical advantage is achieved through the use of two pulling forces, making it easier to handle and transport heavy objects.

2. Right Hand Double Pulley

Similar to its cousin, the right-hand double pulley serves the same purpose as the left-hand double pulley. It is usually positioned on the right side of tools such as lawn mowers, helping in the movement of big loads with reduced effort.

3. Center Pulley

The center pulley, known as the craftsman lt2000 drive belt pulley, is centrally located and designed to accommodate ropes, wire ropes, or belts. This grooved wheel, also known as a sheave or pulley, plays a crucial role in guiding and supporting the transportation of various objects.

Due to its adaptability, this kind of pulley may be found on a variety of equipment and machines and offers crucial assistance in a broad range of applications.

4. Deck Idler Pulley

The deck idler pulley plays a vital role in maintaining tension on the drive belt and guiding it around the engine. By ensuring a taut belt, it efficiently powers the engine of the machine.

If the belt gets too loose, it may drop off the pulleys or cause the engine to overheat. Additionally, the idler pulley helps maintain proper alignment of the belt, preventing it from rubbing against other components.

5. Self-Tapping Screw Assembly

Self-tapping screws are a specific type of fastener capable of drilling laterally on their own while being screwed into materials such as metal, plastic, or wood.

These screws possess a unique design that enables them to create their own holes during insertion, making them highly suitable for various applications in metalwork, plastic fabrication, and woodworking.

6. Deck Belt

The deck belt is an essential component of a riding lawn mower, serving as the link between the engine and the blades. It is crucial for the proper functioning of the mower. A worn or damaged deck belt can lead to issues such as engine overheating, misaligned blades, or even engine failure.

To ensure optimal performance, it is important to regularly inspect the deck belt and replace it if necessary. Investing in a new deck belt is a cost-effective measure to guarantee the safe and efficient operation of your riding lawn mower.

Craftsman LT2000 Drive Belt Routing

The proper routing of drive belts is crucial for the efficient operation of a lawn mower’s power system. This section will cover the primary drive belt routing, which transfers power from the engine to the transmission, and the secondary drive belt routing, responsible for driving the mower blades.

Understanding the precise paths designed by the manufacturer ensures optimal power transfer, alignment, and engagement, resulting in peak performance and safe grass cutting.

Primary Drive Belt Routing

The primary drive belt, which transmits power from the engine’s pulley to the transmission’s input pulley, is a crucial part of a lawn mower’s power system. The manufacturer carefully planned the routing of the primary drive belt to ensure effective power transfer and smooth operation.

The belt is usually carefully guided as it is passed around a variety of pulleys, idlers, and tensioners to eliminate any interference or misalignment. The lawn mower may efficiently transfer power from the engine to the transmission and move forward with peak performance by following the advised primary drive belt routing.

Secondary Drive Belt Routing

Lawn mowers with a cutting deck also include a secondary drive belt in addition to the primary drive belt. When engaged, this belt is essential in allowing the mower blades to rotate.

In order to send power to the cutting blades, the secondary drive belt must go from the engine’s pulley to the pulleys on the mower deck.

To ensure optimum tension, alignment, and engagement with the mower deck pulleys, the manufacturer has created a precise path for the secondary drive belt, similar to how the primary drive belt is routed.

The lawn mower can efficiently and safely cut grass thanks to the secondary drive belt’s precise routing.

Drive Belt Tensioner Mechanism

The tensioner mechanism plays a crucial role in ensuring the proper functioning of the drive belt system. It comprises two key components: the primary drive belt tensioner and the secondary drive belt tensioner.

Primary Drive Belt Tensioner

The primary drive belt tensioner, which performs as a key component, is essential for maintaining the proper tension in the primary drive belt. Its main goal is to keep the belt firmly in place when in use, eliminating any chance of slippage and ensuring an efficient transfer of power.

By carefully carrying out this responsibility, it enables the various parts to function smoothly and guarantees that the machinery performs at its best.

Secondary Drive Belt Tensioner

The secondary drive belt tensioner takes on the duty of maintaining the precise tension required for the secondary drive belt in a way similar to that of its counterpart, the primary drive belt tensioner. The mower deck’s flawless operation when it is actively engaged is ensured by this vital device.

It enables the smooth operation of the deck, resulting in effective cutting and a well-kept grass by consistently maintaining the right tension. The secondary drive belt tensioner is essential to the overall functionality and longevity of the machinery, ensuring that it performs to its fullest potential.

Craftsman LT2000 Drive Belt Working Mechanism

The craftsman lt2000’s drive belt is essential to the operation of this well-liked riding lawn mower. It allows for the transmission of power from the engine to move the mower forward or backward.

The mower deck is furthermore engaged by the drive belt, enabling the blades to effectively cut through grass and maintain a nicely trimmed lawn. The drive belt’s mechanism must be understood in order to maintain and repair this vital part. Let us see how it works.

Power Transfer from Engine to Transmission

The craftsman lt2000 engine is essential for sending power to the transmission. The pulley on the engine spins as it hums along, producing rotational force. The primary drive belt, which is attached to the engine’s pulley and transmits the energy to the input pulley of the transmission, harnesses this force.

After entering the transmission, this power is effectively used to move the mower forward or backward depending on the operator’s choice of gear.

Engaging the Mower Deck

The craftsman lt2000 uses the secondary drive belt to activate the mower deck. A remarkable series of events start when the operator pushes the mower deck lever. Upon engagement, the secondary drive belt tightens its hold, igniting the mower deck pulleys.

These pulleys start to rotate, giving the mower blades their energy. This rotating force gives the blades the ability to carry out their main duty of deftly slicing through the grass, leaving behind a well-kept lawn.

How to Remove Craftsman LT2000 Drive Belt: Follow the Detailed Guide

Here are the necessary steps to follow;

- Step 1: Start by leveling the mower. Be sure to apply the parking brake firmly to prevent any inadvertent movements.

- Step 2: While repairing the drive belt, it is imperative to detach the spark plug for safety reasons to prevent unintentional engine starts.

- Step 3: Next, find the drive belt routing diagram, which is normally either on the mower deck or beneath the operator’s seat. This diagram is a helpful roadmap throughout the entire procedure.

- Step 4: Using the diagram as a guide, gently adjust the tensioner mechanism to release the drive belt’s tension. Take care to avoid hurting yourself or the environment by exercising caution.

- Step 5: Slide the drive belt off the pulleys after the strain has been sufficiently released. Pay close attention and handle the belt gently to prevent harm to the surrounding components.

The order of removal should be followed while replacing a drive belt. Pay close attention to the belt’s proper routing and make sure it follows the diagram. Ensure that the appropriate tension is achieved for the best performance.

You may properly remove and replace the drive belt on your lawn mower by carefully following these instructions, which will enhance its effective operation and increase its lifespan.

Craftsman LT2000 Drive Belt: Maintenance Tips

proper maintenance is essential for ensuring the craftsman lt2000 drive belt’s durability and peak performance. Following a few crucial maintenance advices can help you do this:

Regular Inspection

Check the condition of the drive belt on a regular basis. It’s critical to routinely check the belt for any indications of wear, damage, or cracks. It is crucial to replace the belt right away if you have any problems in order to stop further harm.

Cleaning and Lubrication

Lubrication and cleaning are essential components of drive belt maintenance. Clean the belt and pulleys frequently to get rid of dirt, grass clippings, and debris that might assemble over time. Additionally, it is advised to oil the tensioner mechanism and pulleys in accordance with the manufacturer’s instructions.

Drive Belt Replacement

Drive belt replacing is necessary if there are obvious symptoms of deterioration, fraying, or damage. In these circumstances, it is advised to replace the belt right away to prevent any potential issues. Refer to the drive belt routing diagram and pay close attention to the manufacturer’s instructions to ensure the proper replacement method.

The craftsman lt2000 drive belt can operate smoothly and have a longer lifespan if you follow these maintenance recommendations to keep it in top condition. Remember that maintaining the best possible performance from your drive belt requires routine checks, maintenance, and prompt replacement.

Troubleshooting Common Drive Belt Issues

Drive Belt Slippage

The drive belt may need to be adjusted or replaced if it slides or fails to transfer power adequately. It is essential to inspect the tensioner mechanism and adjust the tension as needed.

Excessive Drive Belt Wear

The drive belt may experience excessive wear as a result of debris accumulation or insufficient tension. The drive belt must be routinely cleaned and ensured to be properly tensioned in order to avoid premature wear.

Drive Belt Misalignment

It’s important to check for any obstructions or broken parts if the drive belt appears to be out of alignment or disengages from the pulleys while in use. Once the belt is properly aligned and adjusted or replaced, you should do it in line with the drive belt diagram.

People Also Ask

What is the Craftsman LT2000 drive belt size?

Depending on the particular model and year of the mower, the craftsman lt2000’s drive belt size are different. It is advised to consult the mower’s handbook or get in touch with the manufacturer for accurate information in order to identify the proper drive belt size for your mower.

How do you adjust a drive belt?

A drive belt can be adjusted by finding the tensioner mechanism and adhering to the manufacturer’s guidelines. Typically, you can change the tension by either altering the tensioner bracket’s position or loosening or tightening the tensioner pulley, depending on the manufacturer’s instructions.

How long is the drive belt on a Craftsman riding mower?

Depending on the type and deck size, the drive belt length on a Craftsman riding mower, such as the LT2000, might vary. It is advised to use the drive belt diagram or the mower’s handbook to determine the drive belt’s exact length.

How do you tighten the drive belt on a Craftsman riding lawn mower?

You should first find the tensioner mechanism on a Craftsman riding lawn mower before tightening the drive belt. Once it is, use the drive belt diagram to determine the proper process or follow the manufacturer’s directions to adjust the tension as necessary.

How do you install a ground drive belt?

Depending on the type of the Craftsman riding mower, the ground drive belt installation procedure may differ. It is advised to refer to the mower’s handbook or follow the drive belt installation guidelines provided by the manufacturer for comprehensive information on how to appropriately install the ground drive belt.

Last Few Words

Maintaining the operation and longevity of your craftsman lt2000 riding lawn mower depends on your ability to understand the drive belt diagram. Now, you can execute maintenance activities and solve typical faults by understanding the drive belt components, routing, tensioner mechanism, and how it operates.

The craftsman lt2000 riding mower will operate at peak efficiency and have a longer lifespan if the drive belt is regularly inspected, cleaned, lubricated, and replaced in a timely manner.